Posted 1353 days ago

Author: Dr. Michael Snider

Sponsored by 3M

In our last article, we discussed a history history of the CEREC system, as well as a limited story of the materials that are Avia times for use in the CEER system. In this article, we will discuss one of the most important influence materials in the market today: Zirconia.

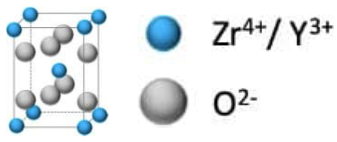

The zirconia that we all know in our restorative cases, actually begins to Quike. The zrsio4) is the initial silicate mineral that is extracted from deposits in Africa and Australia.1 After the zirch is purified to produce zirchon powder, metal oxides are added to dust.

Aluminum is then added to avoid water corrosion, and Trio is added to stabilize the tetragonal phase of the zirconium.

Figure 1. Classic “3y”, High Force Zirconia

The benefits of the circumstances were huge for us as doctors. We had an incredible force in a monolithic restoration. The need to join as with other high -resistance glass ceramics was eliminated. Due to the unique characteristics of how zirconia restorations are frequent and sinteric, we had a multitude of options regarding margin design, preparation design and even conventional cementation. The only thing that was missing was the ability to produce this restoration chair. Of course, the restoration could be ground in our office, but the sintering times required for the ziron did not make them adequate for the restorations of the chair.

All of that changed with the launch of the Cerec Speedfire oven of Dentspply Sirona associated with the ability to dry the factory. The necessary hours for sinter zirconia restorations were reduced by less than 30 minutes. With the technological advances made by Dentspple Sirona, Zirconia was now ready for the chair application

Figure 2. Dentspy Sirona Ploona and Figure 3. Hortor Cerec Speedfire

The ability to produce the president of thesis restorations now was exciting for many of us. But, I still found myself using high strength glass ceramics due to its upper aesthetics. The initial circumstances that most of us were using were 3 and circumstances. They were extremely strong materials, but they had little translancy and looked quite opaque in the mouth.

So what is the true story of “YS” in today’s circumstances? Since we have so many options now available to us, let’s go through what are the real differences. I am sure that he has already heard the terms 3y, 4y and 5y in reference to the circumstance, but what do the real thesis terms mean?

Let’s start by discussing why and Ttry to the circumstance. We yield early that helps stabilize the tetragonal phase of the zirconium. The amount of ittria in the composition of the ziron directly affects resistance and translucence by adjusting the phase composition. In other words, the more and to the composition, the more cubic phase of the circumstances in the product.

Figure 4. Comparison of monoclinic, tetragonal and cubic circumstances

The tetragonal phase of the ziron is responsible for the force that we all love with the circumstance. The tetragonal phase increases the force by propagation of annoying cracks through phase transformation.2

Figure 5. Tetragonal phase, force

The cubic phase of the circumstance is responsible for the transludence of the material. The cubic phase increases translucence by reducing the dispersion of light and deflection. As the material has less tetragonal phase, there is less refraction of light in tetragonal limits.

Figure 6. Cubic phase, translucence

The 3 and zirconia will be similar to Cerec Zirconia that many of you may have used in the past. With only 3% composition of Yttria, 90% of the material is in the tetragonal phase and only 10% in the cubic phase. These materials are extremely strong, but not very aesthetic.

Zirconia 5 and acts as a completely deferred material. With a composition of 5% of Yttria, we have only 45% of the circumstances in the tetragonal phase, and we have 55% of the circumstances in the cubic phase. This material has a remarkably better aesthetic. But, by obtaining aesthetics, we have lost strength. We have moved almost 1400mpa with our 3y zirconies and now we are around 800mpa with our 5y zirconies.

This is the reason why the 3M ™ zone presided has been unique to me in my practice. This zirconia is a zirconia of 4y, or we have a 4% composition of yttria. This composition makes the 3M ™ circumstant zone the best of both worlds in my practice. I still get the strength I want from a zirconia restoration to 1000MPA, but with the increase of yttria, I also obtain the translucidity that I like compared to the circumstances 3y. 3M ™ Zirconia chair is a perfect combination of beauty and aesthetics.

Figure 7. 3y vs 4y vs 5y

Figure 8. Comparison of resistance between materials with different compositions of Yttria.

Figure 9. Comparison of translucidity between materials with different compositions of Yttria

In our next article, we return to more clinical applications or 3M ™ Chairside. We will review the effects of Di ent ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff ff. We will also discuss the effects of polishing restorations and surrounding girlfriend; Is it a preferable one about another?

See you soon!

References:

1. Burgess, J. Zirconia: the material, its evolution and composition. COMPENDIOK. 2018.

2. 3m internal data.