Tim Cook, Executive Director of Apple Inc., speaks the duration of a “first tool in the tool” at the TSMC facilities in construction in Phoenix, Arizona, USA, on Test Day, December 6, 2022.

Caitlin O’Hara | Bloomberg | Getty images

When President Barack Obama asked the deceased CEO of Apple Steve Jobs about doing an iPhone in the US, the works did not put words.

“Those works will not return,” Jobs said at a dinner with Obama in 2011.

The president of the United States and the CEO of Apple I have changed, but the ambition of an iPhone “made in the United States” remains.

Defending its “reciprocal tariffs”, the White House said this week that President Donald Trump believes that the United States has the workforce and resources to build iPhones in the CEO of Apple of the US exensive at best.

As it is largely a theoretical exercise, there is a wide range of conjectures on how much an all-American iPhone could cost.

Bank of America Securities Wamsi Mohan analyst said in a Thursday note that the iPhone 16 Pro, which currently has a price of $ 1,199, could increase 25% depending on labor costs alone. That would make it a device of approximately $ 1,500.

Dan IVES of Wedbush set $ 3,500 as the price of the US iPhone. Shortly after the fee announcement last week, estimating that Apple needs to spend approximately three million $ 30 billion to move 10% of its supply chain to the United States.

At the moment, Apple manufactures more than 80% of its products in China. These products now receive a 145% tax when the US is imported to the US after Trump’s tariffs entered into force this week.

Experts say that an iPhone “made in the USA.” It would face serious challenges, ranging from finding and paying a workforce of the United States to the tariff costs in which Apple would incur import pieces to the US. UU. For the final assembly.

There is a broad agreement between analysts and industry observers that it is not likely to happen. Wall Street has doubted for years that Apple would make an American iPhone. “I don’t think it’s one thing,” Laura Martin de Needham joked on CNBC this week.

“It is not a reality that in the framework of imposing rates that this will change the manufacture here. It is foot in the sky,” said Jeff Fieldhack, director of Research at Counterpoint Research.

A man reviews an iPhone 16 Pro as the new smartphones of the iPhone 16 series go on sale in an Apple store in Beijing, China, on September 20, 2024.

Florence lo | Reuters

Apple designs its products in California, but are made by contracting manufacturers, such as Foxconn, the company’s main supplier.

Even if Apple spent heavy to get Foxconn or another partner to accept to build some iPhones in the United States, it would take years to build plants and install the machinery, and there is no guarantee that US commercial policy. UU. It is still applied.

The biggest problem with Uncle Sam’s iPhone is that the United States does not not not make strength with China; He thought that the huge number of workers necessary to build iPhones is one of the attractions for Trump administration.

“The army of millions and millions of human beings screwing small screws to make iPhones, that kind of thing will come to the United States,” said Secretary of Commerce Howard Lutnick on CBS on Sunday.

Foxconn builds iPhones and other Apple products in mass campuses that include bedrooms and ferry. Workers often travel from nearby regions to work on the plant for short periods, and employment increases seasonally in the summer before the new iPhones come out in autumn. The well -greased system helps Apple to pump more than 200 million iPhones per year.

In addition, Foxconn over the years has been the subject of scrutiny for the conditions of workers many times, even in 2011 when the company installed networks around some of its buildings after an eruption of workers suicides. Supervision groups have said that Foxconn’s work is exhausting and that workers are pressed to work overtime.

Despite the working conditions, Foxconn hired 50,000 additional workers in his largest factory in Henan to build enough iPhones before the last September launch of the models, the Chinese media reported last fall.

But Chinese workers are paid much less than US workers. The salary duration per hour The increase in iPhone 16 was 26 yuan, or $ 3.63, with a signature bonus or 7,500 yuan, or around $ 1,000, according to the South China Morning Post. To compare, the minimum wage in California is $ 16.50 per hour.

Mohan de Bank of America Securities estimated on Thursday that the labor cost to gather and try an iPhone in the US.

Apple’s CEO, Cook has also said that another problem is that US workers do not have the right skills. In a 2017 interview, Cook said there are not enough tool engineers in the US.

“The reason is due to the amount of skill in a place, and the type of skill that is,” Cook said when asked at a conference why Apple does so much production in China.

A meeting of tool engineers in China could fill “multiple soccer fields”, but in the United States, it would be difficult to fill one, Cook said.

The most recent effort for Foxconn to move significant production to the US. It was a failure.

Trump announced an investment of $ 10 billion of Foxconn to build plants in Wisconsin in 2017. Apple was never attached to Wisconsin de Foxconn’s location, but that did not impose Trump claiming that Apple Woudd “builds three”

Foxconn changed plans several times for what the Wisconsin plant would produce, but anyone decided to make the duration of the masks of the face be the pandemic, nothing related to electronics. The Foxconn Wisconsin plant was presented as delivering 13,000 jobs, but only created 1,454 jobs.

Duration The pandemic, the plans for the plant were abandoned, and most of the facilities remain impossible sideways.

Apple worked with Foxconn in 2011 to expand iPhone production to Brazil to avoid large import tariffs in that country. The plant is still operational today and will produce iPhone 16 models to help Apple move the United States rates, cordination to recent Brazilian media reports.

But just after the $ 12 billion factory was operational, most of the components were still imported from Asia, and in 2015, four years after the plant was announced, the iPhones made in Brazil were sold for twice the price of iPhones made in China, according to Reuters.

However, recently the efforts of Taiwan Semiconductor Manufacturing Co., the main Apple chips manufacturer have succeeded. TSMC now makes small amounts of avant -garde chips in a new factory in Arizona, and Apple is a committed client.

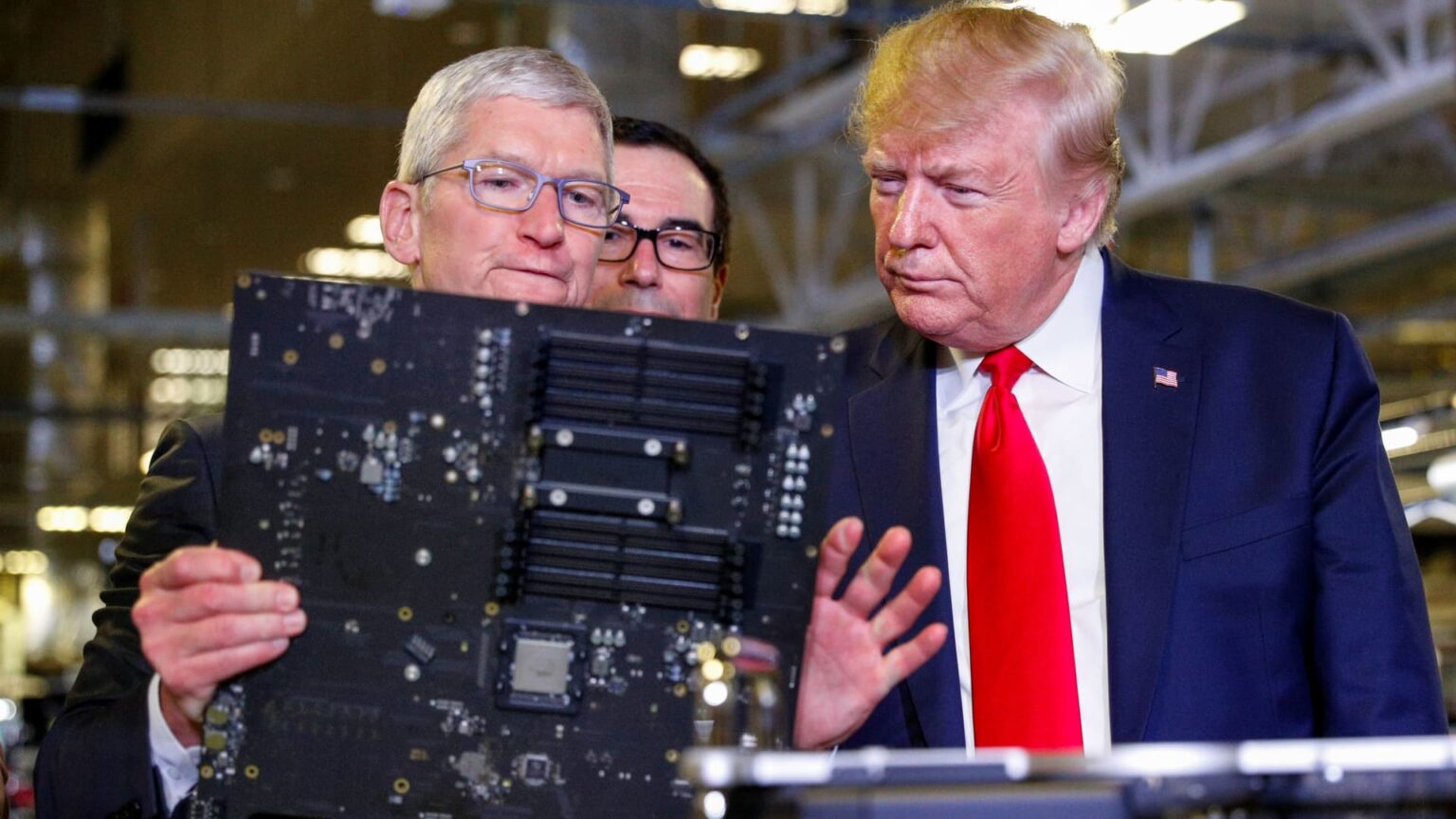

The Apple CEO, Tim Cook, Escorts, Donald Trump, tours Apple’s Mac Pro manufacturing plant with Treasury Secretary Steven Mnuchin looking in Austin, Texas, on November 20, 2019.

Tom Brenner | Reuters

Even if iPhones could be assembled in the United States, much of what enters an iPhone comes from countries around the world, all of which have received rates.

The vast majority of the pieces on an iPhone are made in Asia. The processor is manufactured by TSMC in Taiwan, the screen is produced by South Korean companies such as LG or Samsung, and most other components are made in China.

Apple would face tariffs in most of those parts, according to the values of Mohan or Bank of America, unless you can ensure exemptions for individual pieces. The semiconductors, which are among the most valuable parts within an iPhone, are exempt from tariffs at this time.

Trump on Wednesday put a 90 -day break in most of his rates, but if the pause comes to an end, an iPhone 16 pro max made in Yankee could increase the price by 91% thanks to tariffs and the increase in labor costs, writes Mohan.

“While it may be possible to move the final assembly to the US.

The thinking works closed the idea of an iPhone of America with Obama, Cook has not adopted the same approach without varied.

Instead, Cook has led Apple’s strategy to interact with Trump, including assistance to its inauguration in January. Apple also announced that it will spend $ 500 billion in the US, including in some Houston servers production. Trump regularly quotes the investment with approval.

Duration Trump’s first administration, Cook’s strategy worked.

Althhehoug Trump talked about iPhones of stars and apples construction plants in the United States, the technology company was able to ensure temporary exemptions for many of its products manufactured in China. That meant that Apple didn’t have to pay tariffs on important devices such as the iPhone.

The duration of the offensive of Trump’s first term culminated in the fall of 2019 when Apple extended its commitment to assemble the Mac Pro of $ 3,000 in a flexible factory outside Austin, Texas. Trump toured the factory with Cook.

Before Apple compromises with a red, white and blue iPhone, you can produce some lower volume products or accessories in the United States to enchant Trump, Wall Street analysts say.

“Since we now know that the Trump administration is willing to negotiate, we would not be surprised Thursday.

Apple declined to comment.